According to STANPA, the National Perfumery and Cosmetics Association, in the report of the Radiography of the cosmetics industry of 2024, it is one of the main contributing sectors of the Spanish economy, with a contribution to GDP of 1.03%. In addition, it is a sector that is committed to competitiveness and sustainability, investing 3.4% in R&D&I and generating 21% of science-based employment.

Europe is committed to the development and investment in strategic technologies (STEP) in the areas of digital technologies, clean and resource-efficient technologies and biotechnology. Some of the digital technologies that are promoted are robotics, advanced detection technologies or Artificial Intelligence. These technologies, individually or combined, have great potential for application in the manufacture of cosmetic products to address some of the challenges of the sector, such as process optimization, waste reduction or quality control of 100% of production in real time.

One of the most outstanding advanced detection technologies is photonics, which is the science that studies the generation, detection and application of photons or particles of light. Photonics is the basis of electro-optical devices that are used for data capture, such as image sensors or sensors that are capable of measuring the response of photons in bands of the spectrum invisible to the human eye, but that contain very valuable information related to the density of matter (X-ray sensors) or its composition (infrared sensors). These last devices are the basis of optical spectroscopy, and are being applied to measure the composition in a fast and non-destructive way by measuring how light is absorbed in the spectral bands associated with the main covalent bonds of matter.

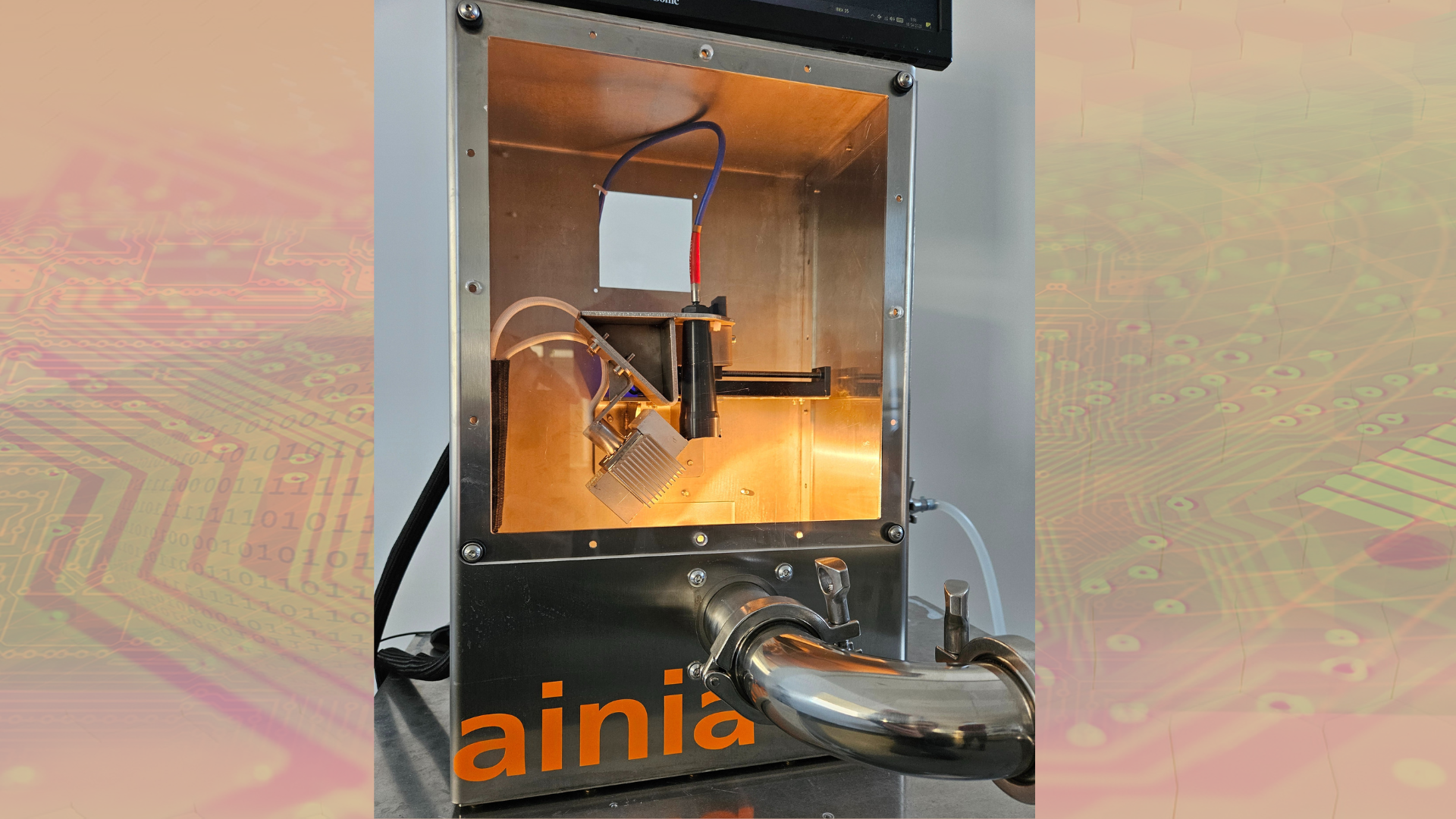

As it is a technique based on the use of light, this type of photonic applications does not require contact with the sample, so they can be applied in process using optical windows in pipes and reactors, maintaining the hygienic conditions of the process.

The latest advances in Artificial Intelligence have made it possible to improve the development of calibration models for different recipes or products in a faster way and with fewer samples, reducing development, implementation and industrial scaling times.

The use of sensors capable of capturing information on key indicators is like putting eyes on manufacturing processes, which is a great help for digitization, allowing to store and analyze data of great value to better interpret processes and help through Big Data techniques to optimize processes, predict critical situations before they occur and reduce manufacturing costs.

In the cosmetics industry, some of the main applications of this type of technologies are the quality control of ingredients to quickly check that they meet the specifications or, for example, the verification of the correct formulation after the mixing and homogenization processes, being able to detect small changes associated with failures in the dosage due to breakage of valves, filters or human errors. Another application is the optimization of manufacturing processes by being able to monitor the reactors in which the emulsion is produced, being able to supervise the process in real time and know when the product has been stabilized and automatically activate the passage to the next phase, with the consequent saving in time and energy. This type of techniques can also be applied in the final product, prior to packaging, to measure the physical and chemical properties of the final product and ensure that they comply with the quality specifications. Finally, it should be mentioned that these advanced detection technologies combined with Artificial Intelligence allow evaluating the effectiveness of cosmetic treatments on the skin thanks to the measurement of indicators such as color, hydration, texture, hydration or the presence of wrinkles and spots.

Therefore, the great advantages of these technologies are the ability to evaluate 100% of the production, the fast measurement in real time without having to wait for laboratory results, the reduction of waste by detecting any incidence early and being able to stop production if specifications are not met or the performance of effectiveness controls of cosmetic treatments quickly and objectively.

At AINIA we have experience in cases of application of this type of technologies for the control of formulation in manufacturing, the detection of defects in finished product or for the monitoring of the effectiveness of treatments on the skin.